High Performance SL 3D Printer with Eps I3200 Head UV Ink Pretreater Oven for DTG Custom Long Sleeve Cotton Hoodie Manufacturing

- Overview

- Recommended Products

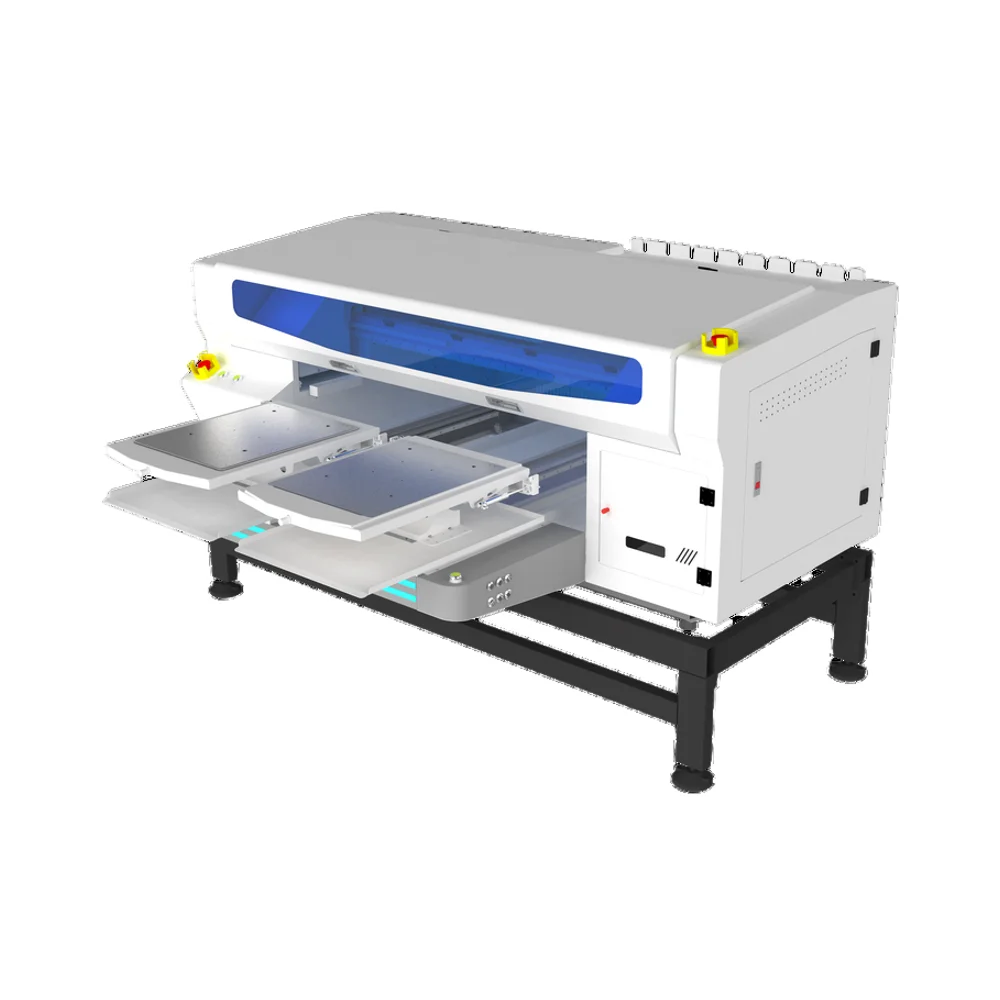

ERA SUB High Performance SL 3D Printer with Eps I3200 Head UV Ink Pretreater Oven is built for makers and manufacturers who need fast, reliable, high-quality direct-to-garment printing on cotton hoodies and long-sleeve apparel. This integrated system brings together precision print technology, a tough UV ink setup, and a dedicated pretreatment and curing solution to deliver vivid, durable prints that stand up to repeated wear and wash

At the heart of the machine is the Eps I3200 print head, engineered for consistent droplet placement and smooth gradients on fabric. It handles fine details and solid fills equally well, letting designers reproduce logos, photos, and full-color art with sharp edges and accurate color reproduction. The high-performance SL platform ensures stable motion and repeatable alignment, reducing waste and reprints while boosting throughput for production runs

The included UV ink system provides deep, bright colors that bond strongly to pretreated cotton. These inks cure quickly under the integrated oven, locking pigment into fibers for excellent wash fastness and reduced cracking over time. Whether printing small batches or larger orders of long-sleeve cotton hoodies, this setup cuts drying time and lets you move garments from printer to finishing faster

Pretreatment is handled by the built-in pretreat machine, formulated and calibrated to prepare cotton surfaces for superior ink adhesion. It evenly applies the right amount of pretreatment solution so prints maintain their vibrancy and feel soft to the touch. This step is crucial for dark and colored garments and helps avoid common issues like ink bleeding or poor wash performance

The oven is tuned for garment curing, offering adjustable temperatures and airflow to suit different ink loads and fabric types. Together with the pretreatment and UV curing, the system delivers consistent results across multiple sizes and styles, from single hoodies to full production batches

User-friendly controls and straightforward maintenance procedures make the ERA SUB SL 3D Printer practical for shops of all sizes. Operators can quickly set up jobs, tweak color profiles, and monitor production without needing extensive training. Built with durability in mind, the unit is designed for long-term use in busy production environments

ERA SUB’s High Performance SL 3D Printer with Eps I3200 Head UV Ink Pretreater Oven is a complete DTG solution for custom long-sleeve cotton hoodie manufacturing, offering speed, color quality, and reliable durability to help apparel producers scale up with confidence

Sprinkler configuration |

Epson i3200-A1 nozzle X3 |

||

Ink configuration |

CMYK+W paint ink two whites and one color |

||

Suitable for fabrics |

100% cotton, or fabrics with high fabrics, ready to-wear, line, denim, sweatshirt, etc |

||

Nozzle to media height |

3mm-30mm adjustable |

||

Optimal spray height |

3mm |

||

Ink barrel volume |

1500ml |

||

Print wedth |

35*45cm/45*55cm |

||

Overall machine power |

1000w |

||