High Performance SL 3D Printer with Eps I3200 Head UV Ink Pretreater Oven for DTG Custom Long Sleeve Cotton Hoodie Manufacturing

- Overview

- Recommended Products

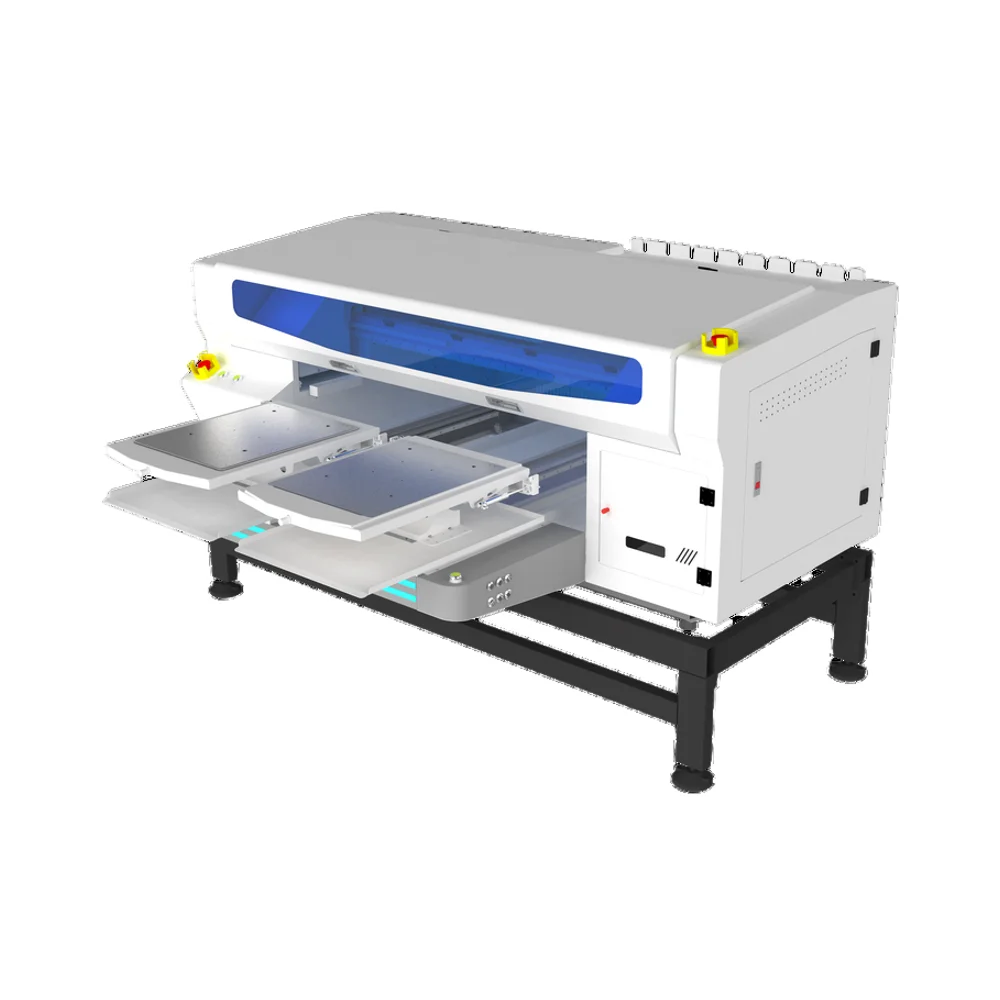

ERA SUB’s High Performance SL 3D Printer with Eps I3200 Head, UV Ink Pretreater, and Oven is built for efficient, reliable DTG printing on long sleeve cotton hoodies. Designed for small to mid-size garment manufacturers and custom print shops, this system combines speed, precision, and user-friendly operation to produce vivid, durable prints with minimal setup.

The core of the system is the Eps I3200 print head, engineered for sharp, consistent ink placement. It delivers high-resolution prints with smooth gradients and fine detail, making it ideal for complex artwork, logos, and photo-quality images on cotton fabric. Paired with the SL 3D printing platform, the head maintains stable performance across long runs, reducing misprints and downtime.

ERA SUB includes an integrated UV ink Pretreater that ensures optimal ink adhesion and color vibrancy on 100% cotton hoodies. The pretreatment unit applies a uniform coating that helps inks bond to fibers, reducing cracking and fading over repeated washes. This step is especially important for long sleeve garments where sleeves and seams require consistent coverage and flexibility.

Built-in oven curing gives prints the finishing heat treatment needed for durability. The oven dries and cures inks evenly, locking in colors and improving wash fastness. Combined with the pretreatment, the curing oven helps maintain print softness so garments feel comfortable to wear while still delivering professional-grade resilience.

The system is optimized for custom long sleeve hoodie production. A specially designed platen and adjustable fixtures accommodate various hoodie sizes and shapes, keeping fabric taut and aligned during printing. This reduces registration issues and ensures each sleeve, pocket, and seam gets consistent print placement. Rapid job changeovers let operators move from one design to the next quickly, supporting on-demand production and limited-run orders.

Operational efficiency is supported by an intuitive control interface that simplifies job setup, color management, and maintenance routines. Automated cleaning cycles and guided alignment tools reduce the need for manual intervention, extending print head life and keeping output quality high. Durable construction and quality components mean the ERA SUB system is built for continuous production with minimal interruptions.

Safety and environmental considerations are included: the UV pretreatment and curing systems are designed to meet industry safety standards, and ERA SUB offers guidance on proper ventilation and ink handling. Consumables and replacement parts are readily available, and technical support options help keep your shop running.

ERA SUB’s High Performance SL 3D Printer with Eps I3200 Head, UV Ink Pretreater, and Oven is a complete DTG solution for producing high-quality custom long sleeve cotton hoodies. It delivers reliable print quality, efficient workflow, and durable results for businesses focused on customization and garment manufacturing

Sprinkler configuration |

Epson i3200-A1 nozzle X3 |

||

Ink configuration |

CMYK+W paint ink - two whites and one color |

||

Suitable for fabrics |

100% cotton, or fabrics with high fabrics, ready to-wear, linen, denim, sweatshirt, etc |

||

Nozzle to media height |

3mm-30mm - adjustable |

||

Optimal spray height |

3mm |

||

Ink barrel volume |

1500ml |

||

Print wedth |

35*45cm/45*55cm |

||

Overall machine power |

1000w |

||