Smooth PLC Semi-Automatic Rhinestone Shaking Machine Efficient Textile Industry Customizable Abnormal Studs Save Time Fast 4

- Overview

- Recommended Products

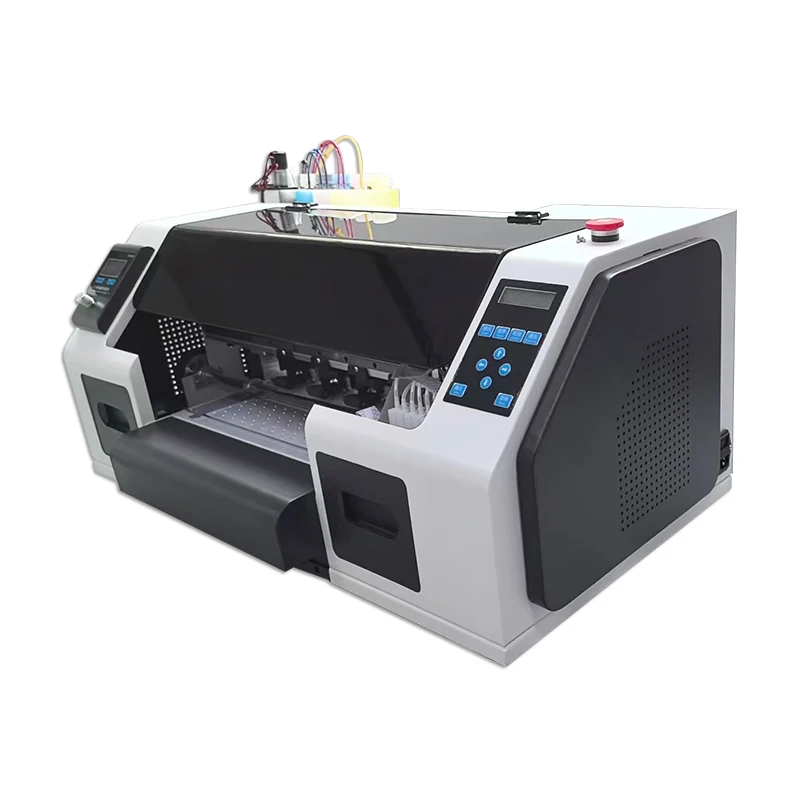

ERA SUB’s Smooth PLC Semi-Automatic Rhinestone Shaking Machine is a reliable, easy-to-use solution designed for textile shops and factories that need fast, consistent rhinestone handling. Built with practical features and a smooth PLC control system, this semi-automatic shaker helps teams save time, cut waste, and keep production moving. The solid frame and simple controls make it a good fit for small to medium operations that want professional results without complex setup.

Key to the design is the PLC-driven operation that keeps shaking consistent and reliable. Operators can set timing and intensity with intuitive buttons and a clear display, removing much of the guesswork from the process. Smooth motion and precise control mean fewer mis-sorted stones and less manual adjustment, so more products move from preparation to application in less time. For busy production lines, this predictability keeps schedules on track and reduces downtime.

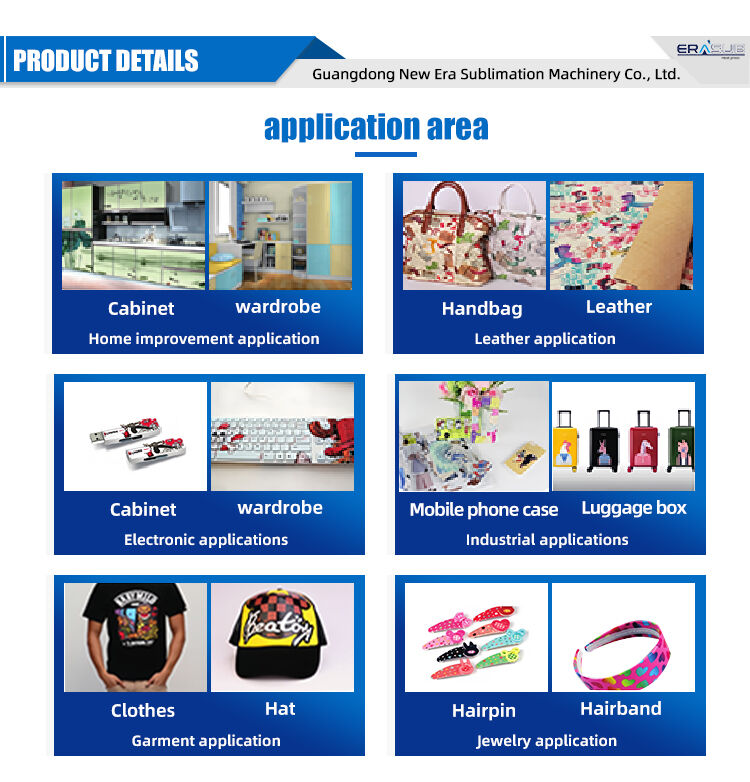

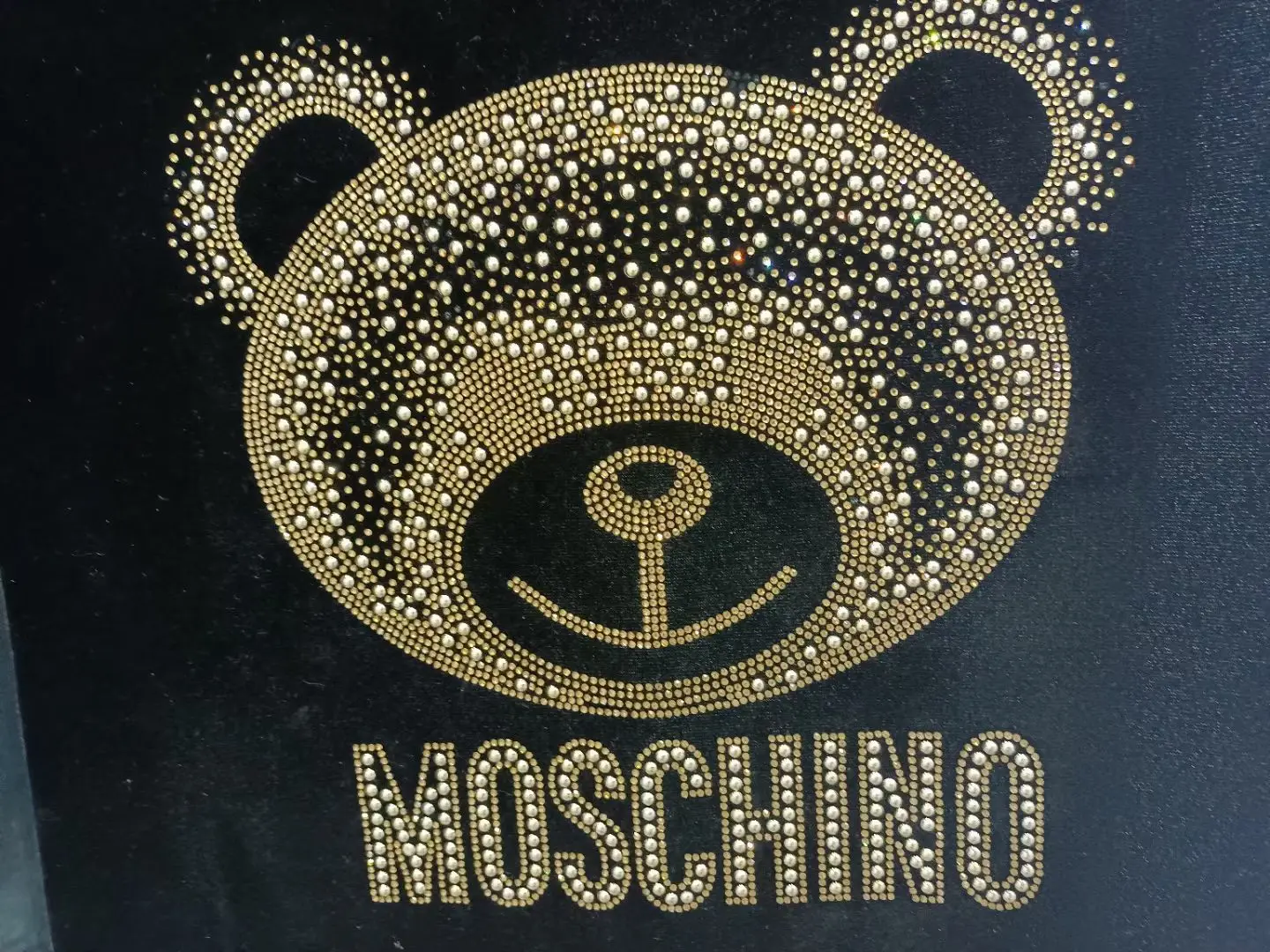

The machine handles a wide range of rhinestone sizes and shapes. It’s designed to sort and feed stones gently but effectively, protecting delicate stones while still clearing out debris and abnormal studs. When odd-shaped or damaged studs are present, the machine’s customizable settings allow operators to tweak shake cycles to minimize jams and segregate problem pieces. That attention to handling reduces rework and improves final product quality.

Installation and operation are straightforward. The semi-automatic format means the shaker does the repetitive work while an operator oversees loading and collecting sorted stones. This blend of automation and human oversight keeps costs down and allows quick adjustments during runs. ERA SUB included practical safety features and a stable base so the machine stays steady during long shifts. Maintenance is also simple: accessible panels and common parts mean quick cleaning and fast part replacement when needed.

For shops that want to save time, the machine is a clear efficiency booster. Faster sorting and fewer stoppages mean higher output with the same staff. The customizable controls let supervisors match settings to different materials and rhinestone types, so a single machine can support multiple product lines. This flexibility makes the ERA SUB Smooth PLC Semi-Automatic Rhinestone Shaking Machine a smart investment for growing businesses.

Compact but robust, the machine balances performance and footprint. It fits easily into existing production areas and integrates with standard workflows. With ERA SUB’s focus on user-friendly design and dependable performance, this shaking machine is an effective tool to streamline rhinestone processing, reduce waste, and help textile operations run smoother and faster

Product Name |

Rhinestone Setting Machine |

Model |

DS-1M960 |

Voltage |

220V |

Power |

300W |

Weight |

124KG |

Product Dimensions |

126x96x92cm |

Application Range |

Rhinestones, Hot Fix Rhinestones, Resin, Glass, Diamond Stickers, etc |