Automatic Laser Cutting Machine for Fabric for Cut Lace on Sublimation Fabric High Precision Laser Engraving

- Overview

- Recommended Products

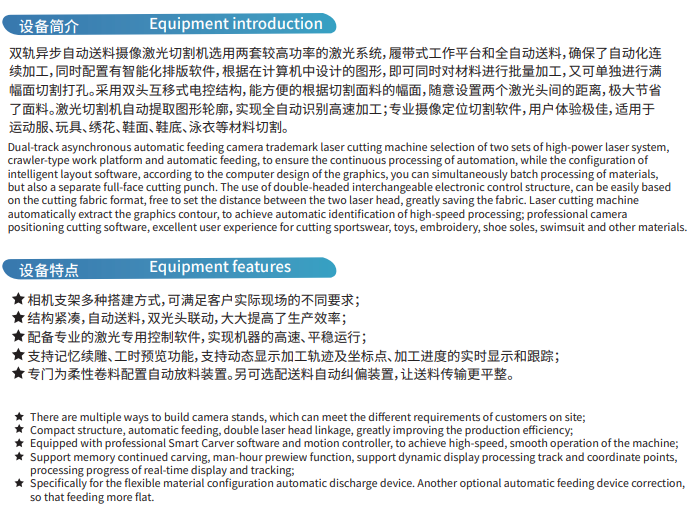

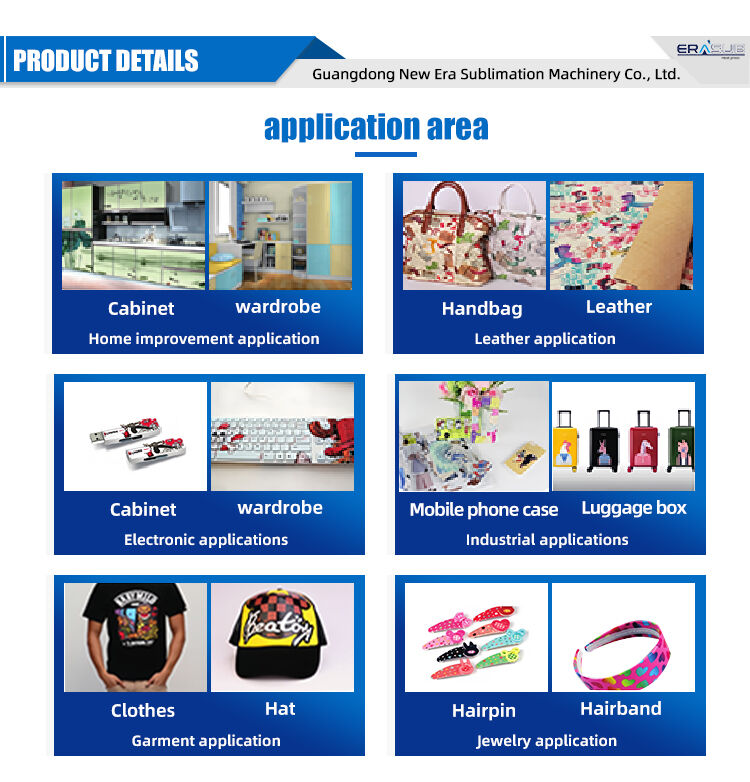

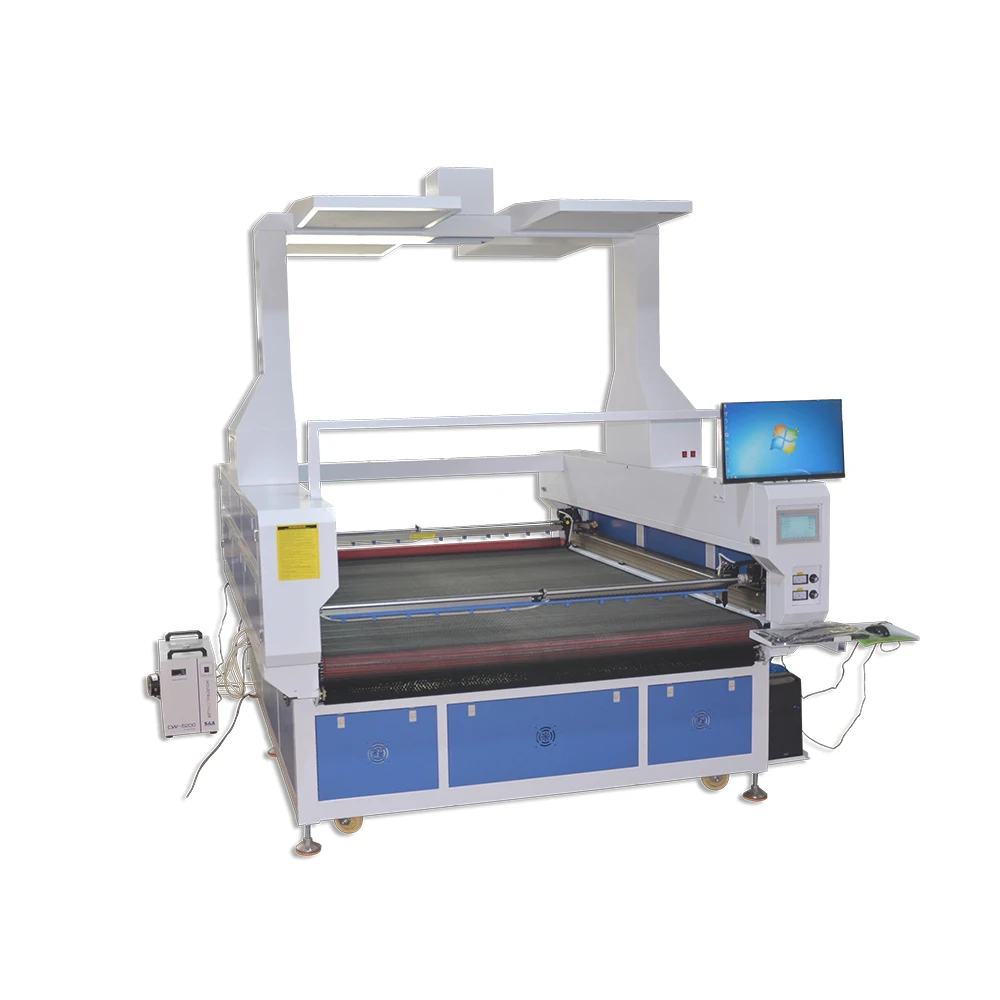

ERA SUB’s Automatic Laser Cutting Machine for Fabric is designed for high-speed, high-precision cutting and engraving of delicate materials such as sublimation fabric and lace. Built for textile workshops, fashion designers, and manufacturers, this machine combines reliable automation with advanced laser technology to deliver clean, consistent cuts and intricate detailing without fraying or distortion.

The machine’s laser system is tuned to work with a variety of fabric types and thicknesses, from lightweight sublimation prints to layered lace panels. ERA SUB’s precision optics and fine beam control allow for micro-level cutting accuracy, producing smooth edges and detailed shapes that preserve fabric integrity. Users can cut complex lace patterns, appliques, and trim with consistent repeatability, ideal for mass production or bespoke garments.

Automation features simplify the workflow. A programmable cutting path and intuitive software interface let operators import designs directly from common file formats. The system supports nesting and pattern optimization to reduce waste and maximize material yield. Auto-calibration routines maintain focus and alignment, while sensors monitor fabric feed to ensure precise placement during continuous runs. These automated routines reduce setup time and operator intervention, increasing throughput and efficiency.

Safety and material care are central to the ERA SUB design. Enclosed cutting chambers and interlock systems protect operators from exposure to laser beams, while an integrated extraction system removes smoke and particulates, preserving air quality and preventing residue on fabrics. The machine includes adjustable power and speed settings so users can find the ideal combination for intricate lace or heat-sensitive sublimation fabrics, minimizing edge discoloration and thermal damage.

Durability and maintenance-friendly engineering ensure long-term reliability. The machine is built with robust frames, corrosion-resistant components, and easy-access service panels for routine cleaning and part replacement. Consumables such as laser tubes and filters are straightforward to replace, and ERA SUB provides clear maintenance schedules to keep performance consistent.

This Automatic Laser Cutting Machine integrates well into production environments. It offers network connectivity for design transfer and production monitoring, and modular add-ons for larger-format cutting, rotary attachments for tubular materials, and multi-head configurations for higher volume needs. Calibration presets for common fabric types speed up changeovers between jobs.

ERA SUB’s Automatic Laser Cutting Machine for Fabric offers precise laser engraving and cutting tailored to the needs of lace and sublimation fabric applications. It balances fine-detail capability with robust automation, delivering reliable, high-quality results for modern textile production

Laser Type |

CO2 Glass Laser Tub |

Cutting Speed |

0-30000mm/min |

Location Precision |

±0.05mm |

Engraving Speed |

0-64000mm/min |

Min. Line Width |

0.1mm |

Cooling Method |

Water Cooling and Protection System |

Controlling system |

DSP High Speed Controller |

Graphic Formats Supported |

AI, DXF, BMP, JPG, CAD, CDR, DWG, PLT, DST, DSB |

Power Source |

AC 220V ±10%, 50/60Hz |

Gross Power |

<2800W |